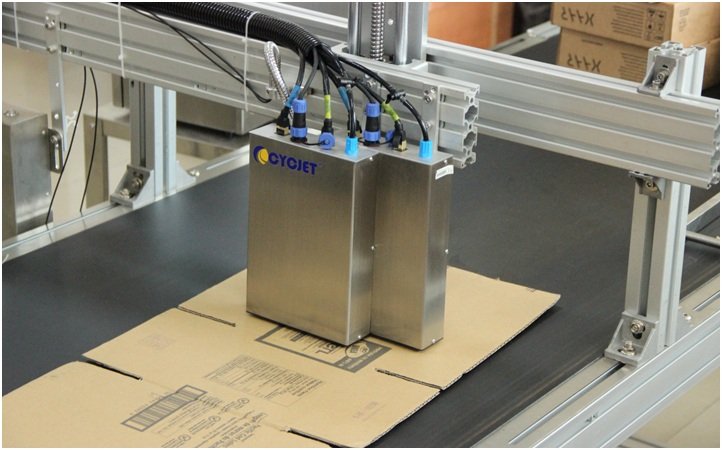

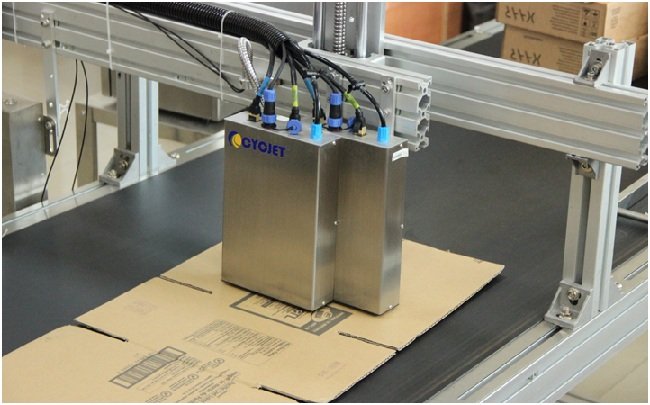

Now, the market demand is changing with each passing day. As a well-known small character inkjet printer brand, CYCJET has been committed to producing high-quality small character inkjet printers and other inkjet equipment. In research and development, CYCJET B3020 small character inkjet printer has been loved by small and medium-sized manufacturers since its inception.

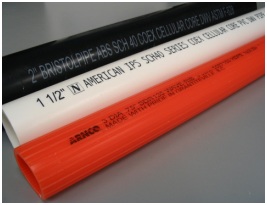

CYCJET B3020 industrial CIJ inkjet printer is specially designed for small and medium-sized manufacturers, providing a coding solution with faster operation speed, higher coding quality and more stable performance.

Product advantages of CYCJET small character inkjet printer:

1. Stable performance.

This series of CIJ inkjet printing machines has stable performance and excellent quality, using an intuitive user interface provided by an internationally renowned manufacturer.

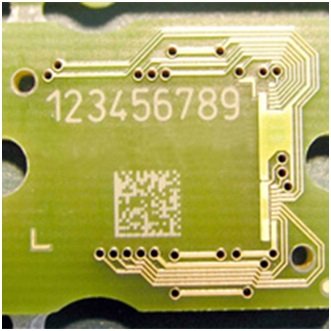

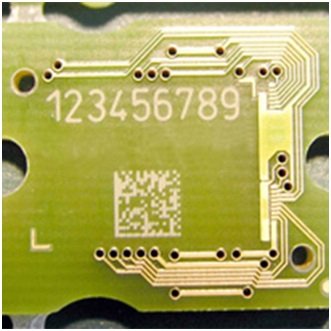

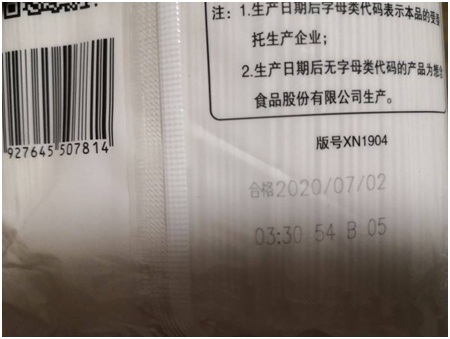

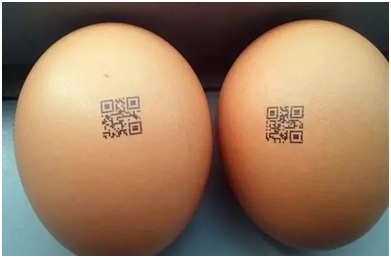

2. Printing quality.

The operator interface provides a selection of predefined options to reduce coding errors and deliver consistently high-quality codes.

3.User confidence.

The large 8” touchscreen interface is easy to use and reduces coding errors. Smart Cartridge technology ensures small character printers always use the correct ink.

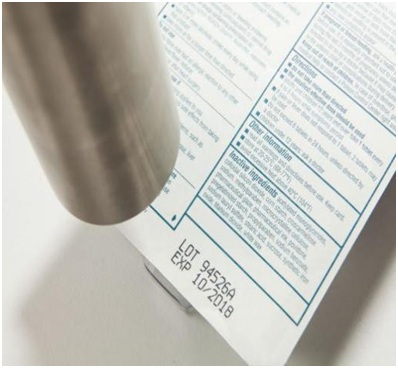

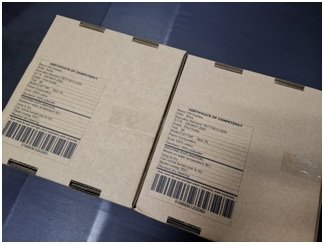

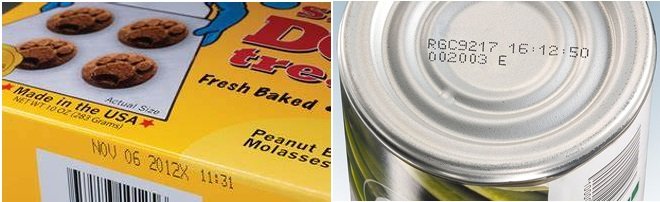

4.Reduce waste.

Costly coding errors can be avoided, eliminating waste and preventing product rejections from customers due to incorrect coding.

CYCJET’s products are easy to use and offer an uptime advantage, allowing manufacturers to spend less time operating packaging printers and can focus on running their business.

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET have more than 16 years of experience for R& D different types of handheld inkjet printing solution, Laser printing solution, and portable marking solution, High Resolution Printing solution in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/

Advantages of

Advantages of