In the pharmaceutical industry, product traceability and compliance labeling are core aspects of ensuring medication safety. Traditional inkjet printing methods suffer from drawbacks such as susceptibility to contamination and easy detachment, while laser marking technology, with its advantages of permanence, high definition, and no consumables, is becoming the ideal choice for pharmaceutical labeling.

The CYCJET CO2 laser coding machine is specifically designed for the stringent requirements of the pharmaceutical industry and is a powerful tool for building a reliable traceability system.

Why Choose Laser Marking Equipment? Four Key Aspects of Pharmaceutical Labeling?

- Permanent Clarity: Labels do not peel off, ensuring readability throughout the entire distribution process.

- Safe and Pollution-Free: No chemical inks, eliminating the risk of drug contamination.

- High Efficiency and Compliance: Meets the demands of high-speed coding on production lines, complying with GMP and other regulations.

- Core of Traceability: Accurate coding is the foundation of “one item, one code” traceability for pharmaceuticals.

CYCJET equipment perfectly meets these needs, providing a solution that surpasses traditional inkjet printing.

Core Advantages of CYCJET CO2 Laser Coding Machines:

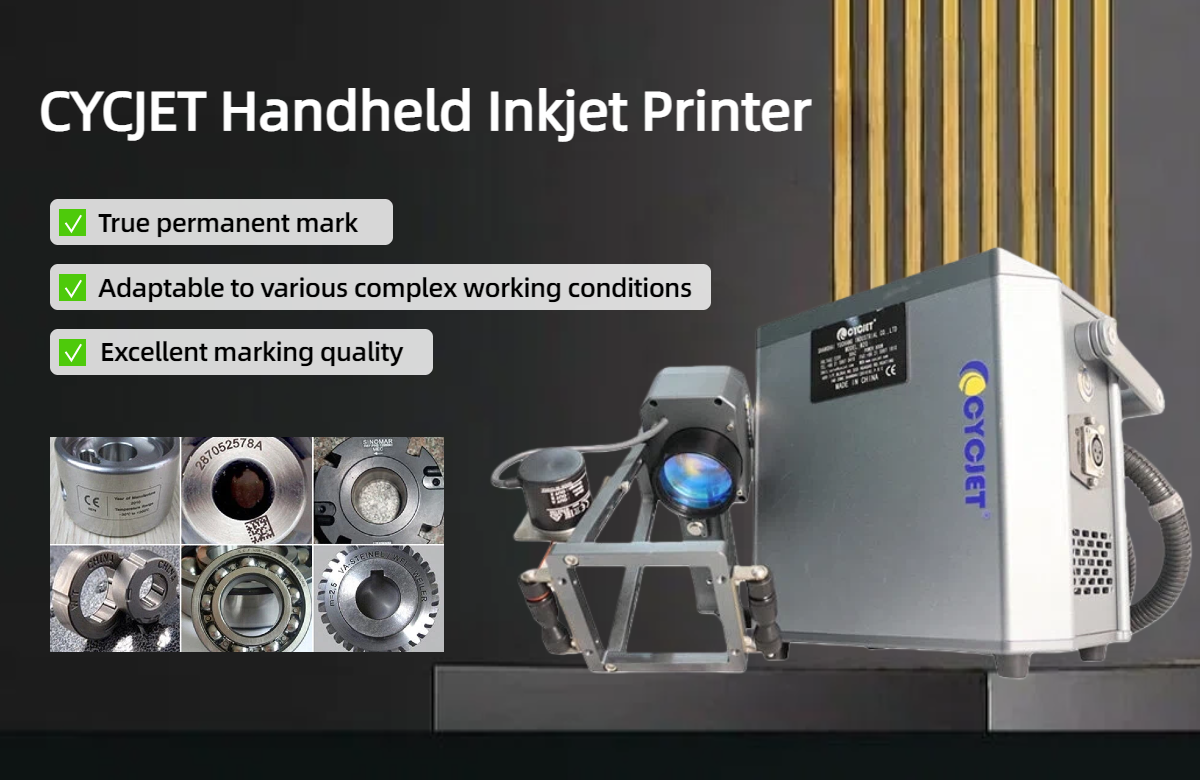

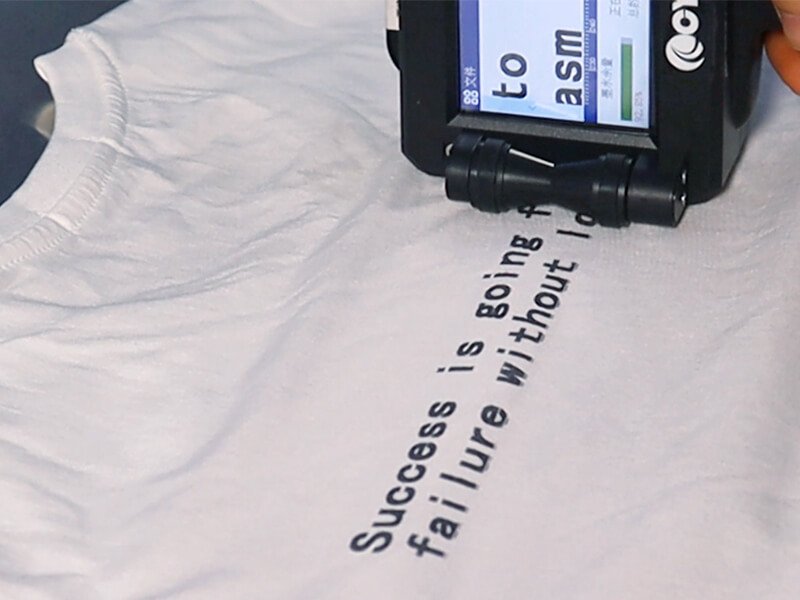

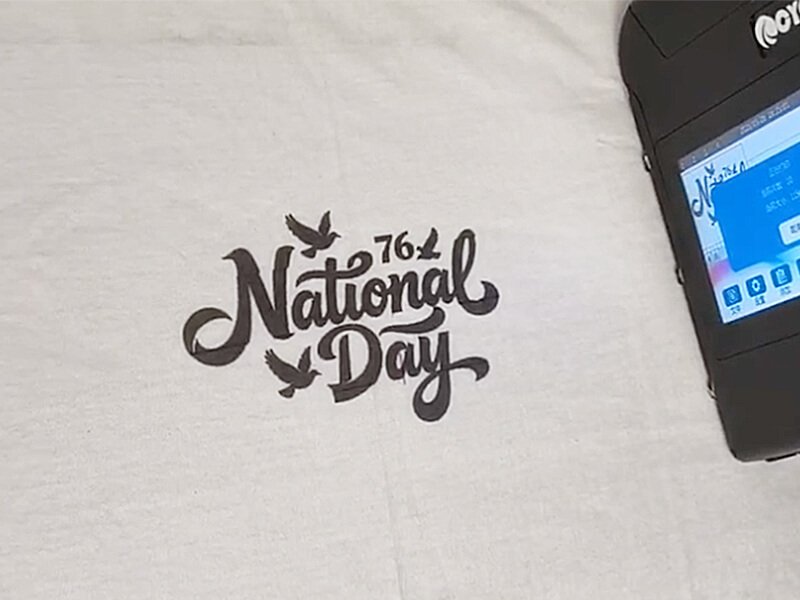

Wide Compatibility: Suitable for various materials including paper pharmaceutical boxes, PVC/PET blister packs, glass bottles, and plastic bottles, providing precise marking.

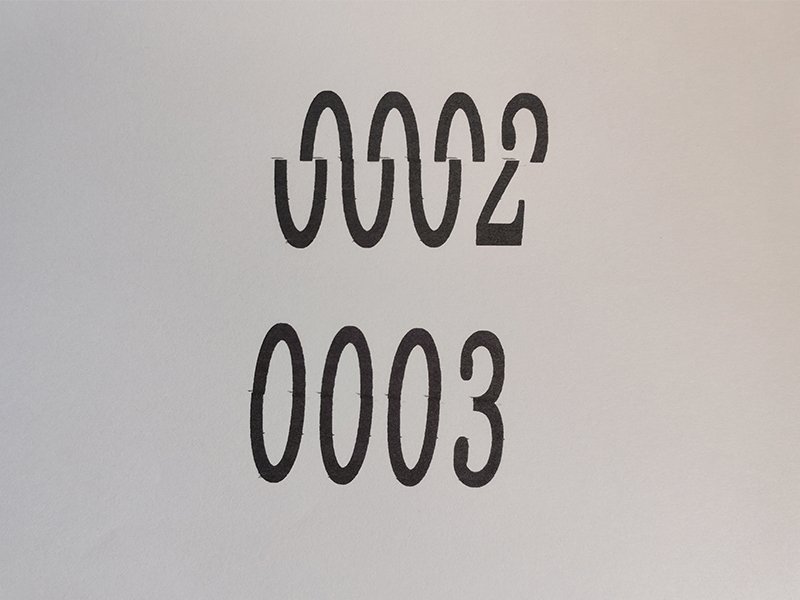

Permanent Marking: Marks are formed through physical alteration of the surface, offering friction and corrosion resistance for long-lasting traceability.

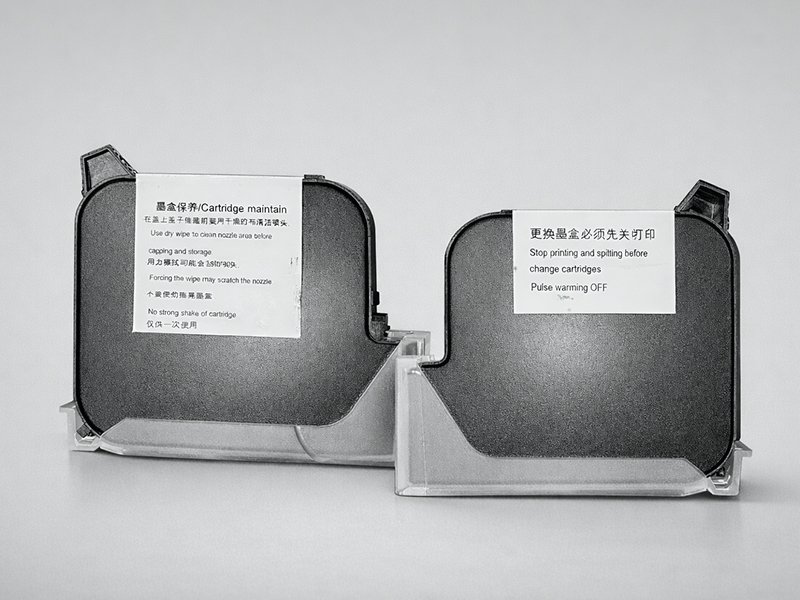

Zero Consumables & Environmentally Friendly: Requires no ink or solvents, significantly reducing long-term operating costs and promoting green production.

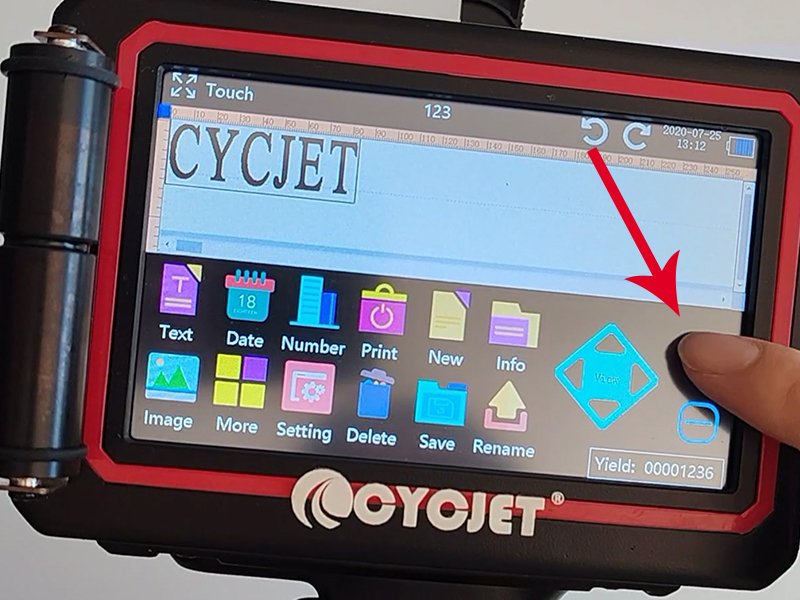

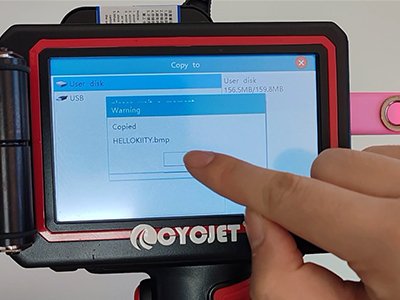

Intelligent Integration:Integrates with ERP/MES systems for real-time data coding and verification, facilitating compliance and traceability.

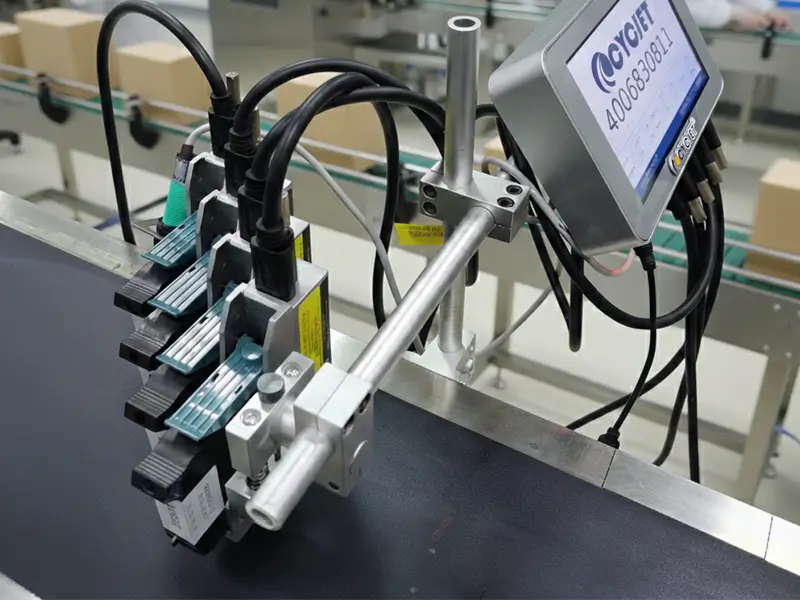

High Speed and Stability: Meets the demands of high-speed production lines, ensuring high equipment reliability and continuous production.

Typical Application Scenarios

- Labeling of drug outer packaging with traceability QR codes, batch numbers, and expiration dates.

-

- Drug information labeling on blister packs.

- Printing of batch numbers on curved surfaces of glass/plastic bottles.

- Integration with the National Drug Traceability Platform to achieve “one item, one code”.

Reasons to Choose CYCJET

CYCJET, a technology brand with over 20 years of experience in the marking industry, is committed to providing highly reliable marking solutions for the pharmaceutical, food, and chemical industries. Its flying laser marking machines not only boast excellent hardware performance but also offer one-stop services including customized software support, on-site debugging, and after-sales training, ensuring companies can quickly implement compliant traceability systems.

In conclusion

As the pharmaceutical industry moves towards full traceability and high-quality development, choosing a reliable, efficient, and compliant marking device is crucial. Driven by technological innovation and guided by industry needs, CYCJET CO2 laser marking equipments help pharmaceutical companies improve marking quality, reduce operating costs, and enhance product safety, thus safeguarding drug traceability and patient safety.About CYCJET:

- CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET have more than 19 years of experience for R& D different types of handheld inkjet printing solution, Laser printing solution, and portable marking solution, High Resolution Printing solution in Shanghai China.

- Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/

Reference Video: https://youtu.be/sRp_kJOp3IE

Facebook: https://www.facebook.com/100064098422560/videos/826499158535395

Linkedin: https://www.linkedin.com/feed/update/urn:li:activity:6986529551359098880