In the cold chain food industry, product identification is like an “identity card,” carrying key information such as production date, shelf life, batch number, etc., and is an important part of ensuring food safety and traceability. Traditional inkjet printers often face many challenges when dealing with cold chain environments, and the emergence of CYCJET small-character inkjet printers has brought a new solution to the industry.

一、 Pain points of traditional inkjet printers:

1. Poor environmental adaptability: The cold chain environment is low temperature and humid, and Traditional Inkjet Printers are prone to problems such as ink freezing and nozzle clogging, which affect the printing effect and stability.

2. Insufficient marking accuracy: The characters printed by traditional inkjet printers are large, making it difficult to clearly present all information on the limited area of the package, affecting readability and aesthetics.

3. High maintenance cost: Traditional inkjet printers have complex structures and cumbersome maintenance, requiring professional personnel to operate, which increases the operating costs of enterprises.

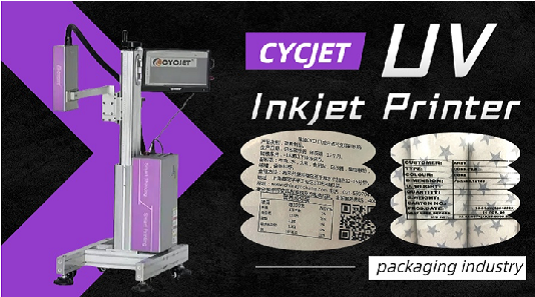

二、Advantages of CYCJET online inkjet printer:

1. Excellent environmental adaptability: The CYCJET small-character inkjet printer adopts advanced ink system and nozzle technology, which can work stably in a wide temperature range of -20°C to 50°C, effectively coping with the challenges of cold chain environment.

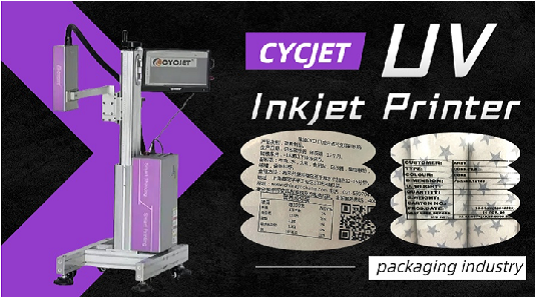

2. High-precision printing: The characters printed by the CIJ Inkjet Printer can be as small as 0.6 mm, with high clarity, and can fully present all information even in a small packaging space, improving the product grade.

3. Intelligent and convenient operation: The CYCJET small-character inkjet printer is equipped with a user-friendly operation interface and intelligent function settings. The operation is simple and easy to understand, and it can be easily used without professionals.

4. Low maintenance cost: The CYCJET small-character inkjet printer has a simple structure design and convenient maintenance, which effectively reduces the operating costs of enterprises.

三、Application of CYCJET small character inkjet printer in cold chain food industry:

1. Production date and shelf life printing: an Industrial Inkjet Printer can clearly print the production date and shelf life to ensure that consumers can accurately understand product information and ensure food safety.

2. Batch number traceability: The CYCJET small-character inkjet printer can print a unique batch number to achieve full product traceability, help companies quickly locate problematic products, and reduce risks.

3. Brand identification and anti-counterfeiting: The CYCJET Small-Character Inkjet Printer can print brand logos, anti-counterfeiting codes, and other information to enhance brand image and prevent products from being counterfeited.

In short, choosing Continuous inkjet (CIJ) means choosing an efficient, accurate, and reliable identification solution! The CYCJET small-character inkjet printer has become a leader in the identification field of the cold chain food industry with its excellent performance and stable performance. In the future, CYCJET will continue to be committed to technological innovation and product development, provide better products and services for the cold chain food industry, and promote the healthy development of the industry.

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET has more than 19 years of experience for R&D of different types of handheld inkjet printing solutions, laser printing solutions, and portable marking solutions, high-resolution printing solutions in Shanghai, China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/

Reference Video: https://www.youtube.com/shorts/u6yVBbw86OU

Facebook: https://www.facebook.com/100064098422560/videos/766386465433516

Linkedin: https://www.linkedin.com/feed/update/urn:li:activity:7165541677128990721